48-Volt Electrical Systems on New ICE and EV Automotive Applications: What Should Your Automotive Program Be Teaching?

The use of 48-volt components in an automotive application is the next logical step in the evolution of automotive electronics. To begin to understand why 48-volt components are only now becoming more talked about we must first go back to why 12-volts was the standard for so long.

12-Volt Systems – A Brief History

The conventional 12-volt system came about in 1955, in response to increased engine displacement, the coming of power windows and other power-hungry devices. Since this introduction, the manufacturers have been looking to maximize the power that is present in the battery pack, and it has largely been unchanged for over 68 years.

Various improvements to the lead acid technology and increased electrical component operation has created a system that is very resilient. Manufacturing processes have brought about the biggest change to the electrical system. The first instances of 48-volt systems have started with the Mild Hybrid applications that are currently present in a majority of OEM’s model lines.

Bottom line: As the devices present on the vehicle continue to require more and more power to operate, the need for a new level of power is required. Forty-eight-volt components allow for a more efficient use of available power and will give the engineer of the vehicle more available power to work with when designing new components.

Mild Hybrid Applications

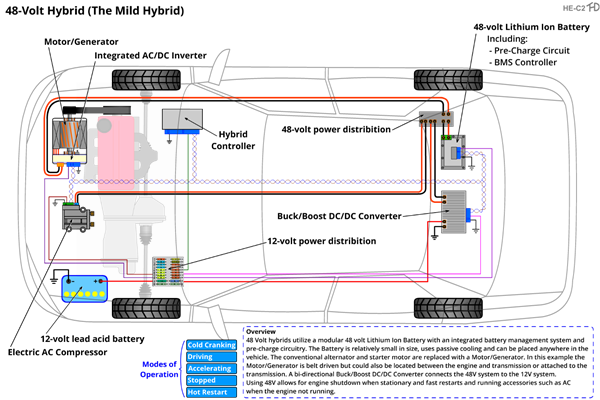

Mild Hybrid Electric Vehicles (MHEV) applications started in the mid to late 2000’s with most manufacturers having a version by the 2010’s. These applications still utilize a conventional 12-volt system for normal electrical operations and primarily use the 48-volt or higher systems to control the stop/start features of the internal combustion engine (ICE).

To gain the most benefit of this type of system, the vehicle shuts off the engine at each stop of the vehicle (for 45-90 seconds), and the engine is shut down. While the engine is shut down the vehicle’s climate control and other components continue to operate through an auxiliary battery pack to keep the occupants comfortable, cool or warm, and entertained. This must all be done through battery power while the ICE is disabled.

Along with these different components, the electrical system must stand ready to restart the ICE within 300 milliseconds of brake pedal release. The ability to operate this type of system on a vehicle will increase fuel mileage and help reduce the carbon footprint of the vehicle. With these different types of systems on this type of vehicle requires a technician/student to be well versed in electrical system operation, different voltages and integrate the use of mechanical components alongside these varying voltages. The use of 48-volts seems to be more common as the cost per application is lower and more attainable for addition to the vehicle.

The Dodge E-Torque, present on some Hemi (and most V6) equipped pickup trucks starting in 2019 model year, allows the vehicle to continue to operate once the engine stops. This type of “stop/start” system provided the truck with 130 ft-lbs. to propel the vehicle while it is accelerating.

starting in 2019 model year, allows the vehicle to continue to operate once the engine stops. This type of “stop/start” system provided the truck with 130 ft-lbs. to propel the vehicle while it is accelerating.

Along with helping propel the truck it increases the MPG of the vehicle by 2 mpg. This system is one of many OEM’s that utilizes an “electric motor helper” or belt alternator starter (BAS) to assist ICE operation to increase power and increase fuel economy. These types of assist or parallel hybrid systems help to extend the applicability of the ICE well into the future.

These types of BAS systems integrate a small 48-volt battery into the vehicle to power and recoup power as the vehicle is operated. The quick restart of the ICE allows seamless operation without operator issues. The cost to implement this type of technology on a conventional ICE is in the range of $1,900-$2,500 on a new Ram. The low cost of implementation will increase adoption of this technology well into the future.

Full EV 48-Volt Adoption

Tesla just announced it would be moving to the 48-volt throughout its electrical systems present on their vehicles. This move has been a long time in the making as the need for increased power within the vehicle has been a battle OEM’s have been working on for decades. Increasing the voltage allows the designers to utilize smaller wiring throughout the vehicle, along with having the ability to offer more features that were not thought possible with 12-volt systems.

Tesla’s switch is just the beginning. As the rest of the industry converts to this type of mindset, the need for a technician to understand what they are working on is key to creating those graduates that have the skills in demand for the workplace.

To carry out heavy calculations and operate the high-power consumption climate control devices, the use of 48-volt power will allow the vehicle to become more efficient. With increased efficiency the vehicle can travel longer on a charge while being able to keep the cabin occupants comfortable, with their increasing electrical demands. The instant gratification of the current generation will be quite pleased to have heated seats that work faster, air conditioning that cools faster and components that generally process their demands almost instantaneously.

Teaching Resources for 48-Volt Power Systems

Conveying the knowledge in these complicated systems requires an automotive instructor with a toolkit of varying animations, videos, curriculum, and support to get these topics across. CDX has developed animations to present this type of content to the learner in a very interactive way. With the Hybrid Stop Start 48v animation, the learner can click through the different types of modes for an immersive experience to understand how these types of systems operate. CDX has developed a whole host of different 2D and 3D animations to help with getting across the complex subject matter that is being discussed. While the instructor is talking through the material, the student is applying it to the animation. After they have a thorough understanding of the material, they are ready to apply this on a real-life vehicle.

To learn more about Mild Hybrid and 48-volt technologies check out Light Duty and Electric Vehicles, First Edition from CDX Learning Systems.

Related Content:

- Lithium Iron Phosphate Battery Cell Chemistry is Taking Over the Automotive Market: What it Means for Auto Educators

- As States Pass Laws Phasing Out Gas-Powered Vehicles, A New Lane Opens for Electric Vehicle Training

- Why the Flipped Classroom Works for Automotive Technology

About the author:

Nicholas Goodnight, PhD is an ASE Master Certified Automotive and Truck Technician and an Instructor at Ivy Tech Community College. With nearly 20 years of industry experience, he brings his passion and expertise to teaching college students the workplace skills they need on the job. For the last several years, Dr. Goodnight has taught in his local community of Fort Wayne and enjoys helping others succeed in their desire to become automotive technicians.